- PRODUCT

- TECHNOLOGY

- COMPANY

- COMMUNITY

Solution come from

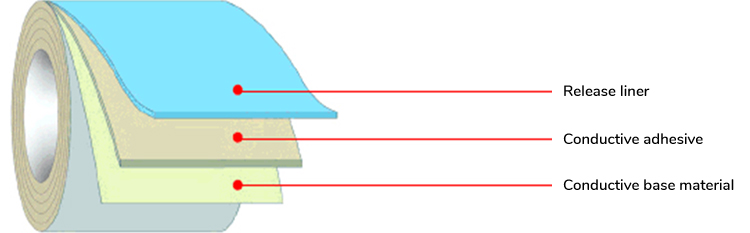

| COATING | Black Coating, PU coating |

|---|---|

| BASE MATERIAL | Woven, Rip-stop, Non-Woven, D.T.Y, Metal Foil – Cu, Al |

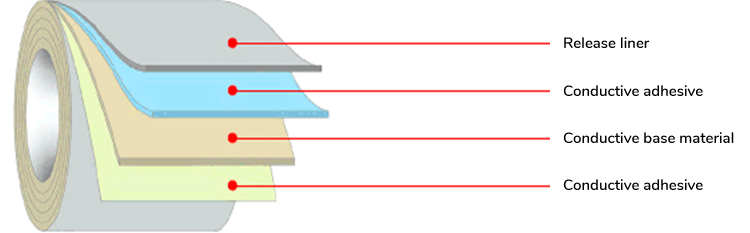

| ADHESIVE | Single Sided, Double sided, Black adhesive, Flame retardant |

| PN | Thickness (µm) |

Plating | Base Material | Adhesive | Adhesive Force (gf/25mm) |

Surface Resistance (Ω/sq) |

Top-bottom Resistance (Ω/in2) |

Remarks |

|---|---|---|---|---|---|---|---|---|

| GAT- A111P |

110±10 | Ni+Cu+Ni | Taffeta | conductive PSA | 1000 | Less 0.2 | Less 0.2 | PU coating |

| GAT- AG105P |

50±10 | Ni+Cu+Ni | Taffeta | conductive PSA | 1000 | Less 0.2 | Less 0.2 | PU coating |

| GAT- AG111P |

110±10 | Ni+Cu+Ni | Taffeta | conductive PSA | 1000 | Less 0.2 | Less 0.2 | PU coating |

| GAT- B111P |

110±10 | Ni+Cu+Ni | Ripstop | conductive PSA | 1000 | Less 0.2 | Less 0.2 | PU coating |

| GAT- B112NF |

120±20 | Ni+Cu+Ni | Ripstop | conductive PSA | 1000 | LESS 0.3 | Less 0.2 | - |

| GAT- C103TP |

30±5 | Ni+Cu+Ni | DTY Ripstop | conductive PSA | 1000 | Less 0.2 | Less 0.2 | - |

| GAT- C105BK |

50±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.2 | Less 0.2 | Black Coaing |

| GAT- C105P |

50±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.2 | Less 0.2 | - |

| GAT- C115 |

150±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.2 | Less 0.2 | - |

| GAT- C120 |

200±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.2 | Less 0.2 | - |

| GAT- CR105 |

50±10 | Ni+Cu+Ni | DTY Ristop | conductive PSA | 1000 | Less 0.2 | Less 0.2 | - |

| GAT- E1015TP |

15±2 | Ni+Cu+Ni | Nonwoven | conductive PSA | 1000 | Less 0.2 | Less 0.2 | PU coating |

| GAT- E115 |

150±10 | Ni+Cu+Ni | Nonwoven | conductive PSA | 1000 | Less 0.2 | Less 0.2 | - |

| PN | Thickness (µm) |

Plating | Base Material | Adhesive | Adhesive Force (gf/25mm) |

Surface Resistance (Ω/sq) |

Top-bottom Resistance (Ω/in2) |

|---|---|---|---|---|---|---|---|

| GAT-C203 | 30±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.1 | Less 0.1 |

| GAT-C205 | 50±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.1 | Less 0.1 |

| GAT-C205L | 50±10 | Ni+Cu+Ni | DTY | conductive PSA | 500 / 1000 | Less 0.1 | Less 0.1 |

| GAT-C207 | 70±10% | Ni+Cu+Ni | DTY | conductive PSA | 1200 | Less 0.1 | Less 0.1 |

| GAT-C210 | 100±10 | Ni+Cu+Ni | DTY | conductive PSA | 1200 | Less 0.1 | Less 0.1 |

| GAT-C210L | 100±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 ± 200 500± 200 |

Less 0.1 | Less 0.1 |

| GAT-C212 | 120±10 | Ni+Cu+Ni | DTY | conductive PSA | 1200 | Less 0.3 | Less 0.1 |

| GAT-C214 | 140±10 | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.1 | Less 0.1 |

| GAT-C214L | 140±10 | Ni+Cu+Ni | DTY | conductive PSA | 500 / 1000 | Less 0.1 | Less 0.1 |

| GAT-C220 | 200±10 | Ni+Cu+Ni | DTY | conductive PSA | 800 | Less 0.2 | Less 0.1 |

| GAT-C220L | 200±10 | Ni+Cu+Ni | DTY | conductive PSA | 500 / 1000 | Less 0.1 | Less 0.1 |

| GAT-C224 | 240±20% | Ni+Cu+Ni | DTY | conductive PSA | 1000 | Less 0.2 | Less 0.1 |

| GAT-CR205 | 50±10 | Ni+Cu+Ni | DTY Ripstop | conductive PSA | 1400 | Less 0.1 | Less 0.1 |

| GAT-E205 | 50±10 | Ni+Cu+Ni | Nonwoven | conductive PSA | 1000 | Less 0.3 | Less 0.1 |

| GAT-E215 | 150±15% | Ni+Cu+Ni | Nonwoven | conductive PSA | 1000 | Less 0.1 | Less 0.1 |

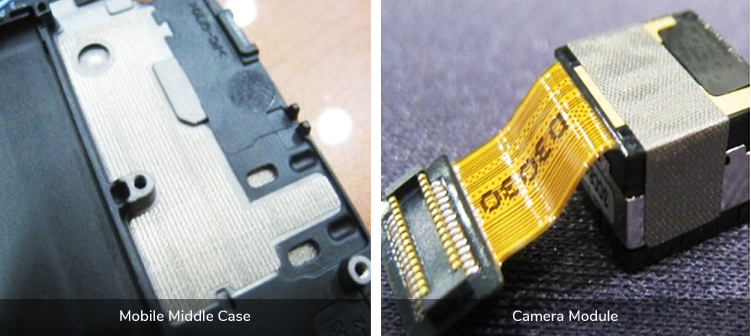

| PN | Thickness (µm) |

Base Material | Adhesive | Adhesive Force (gf/25mm) |

Surface Resistance (Ω/sq) |

Top-bottom Resistance (Ω/in2) |

|

|---|---|---|---|---|---|---|---|

| GAT- EG104D |

45±5 | Cu Foil / nonwoven | double side | conductive PSA (black) |

1500 | Max 0.05 | Max 0.05 |

| GAT- F106 |

60±10 | Aluminum Foil | single side | conductive PSA |

1000 | Max 0.5 (Adhesive side) |

Max 0.1 |

| GAT- F110 |

100±10% | Aluminum Foil | single side | conductive PSA |

1000 | Max 0.5 (Adhesive side) |

Max 0.1 |

| GAT- F114D |

114±10 | Al Foil | single side | conductive PSA |

1000 | Max 0.1 | Max 0.1 |

| GAT- G107 |

70 | Copper Foil | single side | conductive PSA |

1000 | Less 0.1 | Less 0.1 |

| GAT- G107BK |

70 | Copper Foil | single side | conductive PSA |

1000 | Less 0.1 | Less 0.1 |

| GAT- 39ULB |

60±10 | Al Foil / Nonwoven | single side | conductive PSA |

1000 | Less 0.1 | Less 0.1 |

| GAT- G2045 |

45 ±10 | Copper Foil | single side | conductive PSA |

1500 | Less 0.2 | Less 0.05 |

EMP® Series means that EMI TAPE’s EMI absorbers products which has been designed and developed by EMI TAPE. EMI absorbers are used at electronic equipment for EMI noise suppressing by its high magnetic loss. Also it could be used for improvement of signal inductance and wireless power charging system of smart phones. Because EMP® Series is composed of soft magnetic powders and special polymers, it has good properties like as permeability, flexibility and stability. EMI absorbers could available for hybrid types like as conductive aluminum or copper foil laminating materials and black treatment of the surfaces. Also EMI absorbers could be applied in electronic fields of digitizer, NFC, WPC modules and EMI noise source such as FPCB, semiconductors, WLAN and high frequency band noise absorbing for military, medical equipment and satellites.

| Permeability | Thickness (mm) |

Effective frequency (Hz) |

Surface Resistance (Ω/□) |

Temperature range (℃) |

Width (mm) |

Length (mm) |

roll type 가능여부 |

|---|---|---|---|---|---|---|---|

| 10±10% (at 3 MHz) |

0.1 / 0.5 / 1.0 / 1.5 | 0.1GHz to 10GHz | Min. 1 × 1012 | -20 ~ 85 | 250 | - | ROLL |

| 30±10% (at 3 MHz) |

0.1 / 0.5 / 1.0 / 1.5 | 0.1GHz to 10GHz | Min. 1 × 1012 | -20 ~ 85 | 250 | - | ROLL |

| 50±10% (at 13.56 MHz) |

0.03 / 0.05 / 0.1 / 0.2 | 0.1GHz to 10GHz | Min. 1 × 107 | -20 ~ 85 | 210 | 300 | A4 |

| 110±10% (at 3 MHz) |

0.03 / 0.05 / 0.1 / 0.2 | 0.1GHz to 10GHz | Min. 1 × 108 | -20 ~ 85 | 210 | 300 | A4 |

| 130±10% (at 3 MHz) |

0.03 / 0.05 / 0.1 / 0.2 | 0.1GHz to 10GHz | Min. 1 × 108 | -20 ~ 85 | 210 | 300 | A4 |

| 150±10% (at 3 MHz) |

0.03 / 0.05 / 0.1 / 0.2 | 0.1GHz to 10GHz | Min. 1 × 108 | -20 ~ 85 | 210 | 300 | A4 |

| 180±10% (at 3 MHz) |

0.03 / 0.05 / 0.1 / 0.2 | 0.1GHz to 10GHz | Min. 1 × 108 | -20 ~ 85 | 210 | 300 | A4 |

| 200±10% (at 3 MHz) |

0.03 / 0.05 / 0.1 / 0.2 | 0.1GHz to 10GHz | Min. 1 × 108 | -20 ~ 85 | 210 | 300 | A4 |

| 220±10% (at 3 MHz) |

0.03 / 0.05 / 0.1 / 0.2 | 0.1GHz to 10GHz | Min. 1 × 108 | -20 ~ 85 | 210 | 300 | A4 |

| 250±10% (at 3 MHz) |

0.03 / 0.05 | 0.1GHz to 10GHz | Min. 1 × 109 | -20 ~ 85 | 210 | 300 | A4 |

| 280±10% (at 3 MHz) |

0.03 | 0.1GHz to 10GHz | Min. 1 × 1010 | -20 ~ 85 | 210 | 300 | A4 |

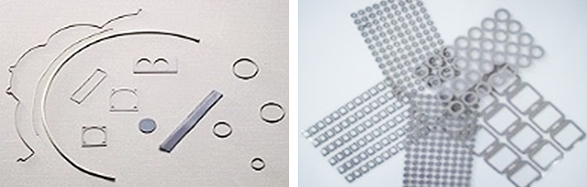

EMI TAPE offers a broad range of the most advanced and sophisticated EMI shielding gaskets. Nickel plated fabric provides high conductivity and shielding effectiveness from 10MH to 10GHz. The core of polyurethane foam in a high resiliency provides high elasticity and very good self-stability.

Easy to process and cut. Various sizes and shapes are available.

| Item Properties | Non-Conductive Tape | Conductive Tape | Test Method |

|---|---|---|---|

| Thickness(µm) | 140 ± 10 | 120 ± 10 | JIS Z 0237 |

| Adhesion(gf/25mm) | 2200 ± 200 | 1000 ± 100 | JIS Z 0237 |

| Tack(gf/5mm) | 1100 ± 100 | - | ASTMD 2979 |

| Holding Power | Less than 0.5(80℃, 1Kg) | - | NS Z 0237(80℃, 1Kg) |

| Volume Resistive (Ω/㎠) | - | 9.27 X 1015 | - |

| Properties | Unit | Spec | Result | Test Method |

|---|---|---|---|---|

| Density | Kg/ | 45+3 | 4.70 | JSS-K-6401 |

| 25%ILD | Kg/ 313㎠ | 30-35 | 34.38 | JSS-K-6401 |

| Tensile strength | Kg/㎠ | 1.5min | 1.869 | JSS-K-6401 |

| Ball rebound | % | 50min | 52 | JSS-K-6401 |

| Tear strength | Kg/㎝ | 0.40min | 0.087 | JSS-K-6401 |

| Flex | % | 5max | 4.87 | JSS-K-6401 |

| Compression Fatigue set. (70℃, 22hs, 50%) |

% | 6max | 4.53 | JSS-K-6401 |

| Elongation | % | 120min | 122.43 | JSS-K-6401 |

| Flame retardant | cm/min | pass | pass | Fmvss#302 |

Can be produced in suitable various foams in structure and use of attachment

The Conductive Silicone is filled with metal filler. It provides high electric conductivity, shielding and moisture sealing. This item is manufactured in sheets, molded type, extrusion type and film type by request. Conductive Silicone Gasket can be used in applications where it is needed for excellent shielding, high conductivity and long term stability For example, telecommunication, information technology, medical and industrial electronic equipment markets are major applicable fields.

EMTSG / EMTOG / EMTDG / EMTWG Series

EMTSCD / EMTSCO / EMTSCOO / EMTSCDO / EMTSCRO / EMTSCR Series

| Conductive Filler | SC(Ag/Cu) | SA(Ag/Al) | NC(Ni/Gr) | |

| Binder | Silicone | Silicone | Silicone | |

| Electrical Properties |

Volume Resistivity (Ω·cm) |

0.02 | 0.08 | 0.10 |

| Shielding Effectiveness(dB) |

> 60 | > 60 | > 40 | |

| Physical Properties |

Specific Gravity | 3.7 (±0.3) | 1.8 (±0.3) | 2.0 (±0.3) |

| Hardness (Shore A) | 65 (±5) | 65 (±5) | 60 (±5) | |

| Tensile Strength (kgf/㎠) | 30 (430psi) | 20 (285psi) | 20 (285psi) | |

| Tear Strength (kN/m) | 6 | 5 | 6 | |

| Elongation (%) | 200 | 200 | 200 | |

| Service Temp. (℃) | - 50 ~ 120 | - 50 ~ 120 | - 50 ~ 120 | |

| Thermal Conductivity |

Vertical (W/m·K) | 1.1 | 2.3 | 0.8 |

| Horizontal (W/m·K) |

1.3 | 1.9 | 1.6 | |

P/N : EMTSG - AAA

(1) - BBB

(2)

P/N : EMTOG - AAA

(1) - BBB

(2)

P/N : EMTDG - AAA

(1) - BBB

(2)

P/N : EMTWG - AAA

(1) - BBB

(2)

P/N : EMTCSO

(1) - AAA

(2) - BBB

(3)

Unit : mm

| P/N | Nominal Diameter | Groove Dimension | NC(Ni/Gr) |

|---|---|---|---|

| W | D | ||

| EMTCSO-071 | 0.71 | 1.40 | 0.46 |

| EMTCSO-081 | 0.81 | 1.42 | 0.56 |

| EMTCSO-102 | 1.02 | 1.59 | 0.89 |

| EMTCSO-122 | 1.22 | 1.65 | 0.94 |

| EMTCSO-135 | 1.35 | 1.78 | 1.40 |

| EMTCSO-157 | 1.57 | 1.70 | 1.32 |

| EMTCSO-178 | 1.78 | 2.13 | 1.42 |

| EMTCSO-188 | 1.88 | 2.21 | 1.52 |

| EMTCSO-203 | 2.03 | 2.16 | 1.65 |

| EMTCSO-216 | 2.16 | 2.46 | 1.75 |

| EMTCSO-229 | 2.29 | 2.59 | 1.85 |

| EMTCSO-236 | 2.36 | 2.49 | 1.91 |

| EMTCSO-254 | 2.54 | 2.79 | 2.08 |

| EMTCSO-262 | 2.62 | 2.90 | 2.13 |

| EMTCSO-284 | 2.84 | 2.97 | 2.29 |

| EMTCSO-302 | 3.02 | 3.15 | 2.44 |

| EMTCSO-318 | 3.18 | 3.43 | 2.59 |

| EMTCSO-330 | 3.30 | 3.51 | 2.72 |

| EMTCSO-340 | 3.40 | 3.63 | 2.79 |

| EMTCSO-353 | 3.53 | 3.73 | 2.90 |

| EMTCSO-373 | 3.73 | 3.96 | 3.05 |

| EMTCSO-401 | 4.01 | 4.22 | 3.28 |

| EMTCSO-432 | 4.32 | 4.52 | 3.53 |

| EMTCSO-478 | 4.78 | 4.92 | 3.91 |

| EMTCSO-495 | 4.95 | 5.11 | 4.06 |

P/N : EMTCSD

(1) - AAA

(2) - BBB

(3)

Unit : mm

| P/N | Nominal Dimension | Groove Dimension | |||

|---|---|---|---|---|---|

| W | H | R | W | D | |

| EMTCSD-140 | 1.62 | 1.40 | 0.81 | 2.57 | 1.12 |

| EMTCSD-163 | 1.40 | 1.63 | 0.70 | 1.96 | 1.32 |

| EMTCSD-173 | 1.57 | 1.73 | 0.79 | 2.13 | 1.42 |

| EMTCSD-178 | 2.03 | 1.78 | 1.02 | 2.95 | 1.47 |

| EMTCSD-198 | 2.39 | 1.98 | 1.19 | 2.92 | 1.65 |

| EMTCSD-216 | 1.57 | 2.16 | 0.78 | 2.23 | 1.83 |

| EMTCSD-226 | 1.98 | 2.26 | 0.99 | 2.57 | 1.88 |

| EMTCSD-239 | 2.39 | 2.39 | 1.19 | 3.25 | 2.03 |

| EMTCSD-241 | 1.78 | 2.41 | 0.89 | 2.46 | 2.06 |

| EMTCSD-279 | 3.81 | 2.79 | 1.91 | 4.19 | 2.41 |

| EMTCSD-292 | 2.60 | 2.92 | 1.30 | 3.40 | 2.51 |

| EMTCSD-345 | 3.15 | 3.45 | 1.55 | 3.44 | 3.01 |

| EMTCSD-396 | 3.96 | 3.96 | 1.98 | 4.93 | 3.48 |

P/N : EMTCSDO

(1) - AAA

(2) - BBB

(3)

Unit : mm

| P/N | Nominal Dimension | |||

|---|---|---|---|---|

| W | H | I | T | |

| EMTCSDO-396 | 3.96 | 1.98 | 1.98 | 1.14 |

P/N : EMTCSOO

(1) - AAA

(2) - BBB

(3)

Unit : mm

| P/N | Nominal Dimension | P/N | Nominal Dimension | ||

|---|---|---|---|---|---|

| O.D | I.D | O.D | I.D | ||

| EMTCSOO-152 | 1.52 | 0.51 | EMTCSOO-300 | 3.00 | 1.40 |

| EMTCSOO-185 | 1.85 | 0.51 | EMTCSOO-318 | 3.18 | 1.14 |

| EMTCSOO-198 | 1.98 | 0.71 | EMTCSOO-330 | 3.30 | 1.14 |

| EMTCSOO-229 | 2.29 | 1.02 | EMTCSOO-368 | 3.68 | 1.50 |

| EMTCSOO-262 | 2.62 | 1.02 | EMTCSOO-396 | 3.96 | 1.27 |

| EMTCSOO-279 | 2.79 | 1.14 | EMTCSOO-457 | 4.57 | 2.00 |

P/N : EMTCSRO

(1) - AAA

(2) - BBB

(3)

Unit : mm

| P/N | Nominal Dimension | ||

|---|---|---|---|

| W | H | D | |

| EMTCSRO-953 | 9.53 | 9.53 | 4.78 |

개인정보처리방침

가나아이앤티는 (이하 '회사'는) 고객님의 개인정보를 중요시하며, "정보통신망 이용촉진 및 정보보호"에 관한 법률을 준수하고 있습니다.

회사는 개인정보처리방침을 통하여 고객님께서 제공하시는 개인정보가 어떠한 용도와 방식으로 이용되고 있으며, 개인정보보호를 위해 어떠한 조치가 취해지고 있는지 알려드립니다.

1. 개인정보의 처리 목적

회사는 다음의 목적을 위하여 개인정보를 처리하고 있으며, 다음의 목적 이외의 용도로는 이용하지 않습니다.

- 문의

2. 개인정보의 처리 및 보유 기간

① 회사는 정보주체로부터 개인정보를 수집할 때 동의 받은 개인정보 보유·이용기간 또는 법령에 따른 개인정보 보유·이용기간 내에서 개인정보를 처리·보유합니다.

② 구체적인 개인정보 처리 및 보유 기간은 다음과 같습니다.

- 문의 : 1년

3. 개인정보의 제3자 제공에 관한 사항

① 회사는 정보주체의 동의, 법률의 특별한 규정 등 개인정보 보호법 제17조 및 제18조에 해당하는 경우에만 개인정보를 제3자에게 제공합니다.

② 회사는 다음과 같이 개인정보를 제3자에게 제공하고 있습니다.

1. <가나아이앤티>

- 개인정보를 제공받는 자 : 가나아이앤티

- 제공받는 자의 개인정보 이용목적 : 문의

- 제공받는 자의 보유.이용기간: 1년

4. 개인정보처리 위탁

① 회사는 원활한 개인정보 업무처리를 위하여 다음과 같이 개인정보 처리업무를 위탁하고 있습니다.

1. <가나아이앤티>

- 위탁받는 자 (수탁자) : 가나아이앤티

- 위탁하는 업무의 내용 : 문의

- 위탁기간 : 1년

② 회사는 위탁계약 체결시 개인정보 보호법 제25조에 따라 위탁업무 수행목적 외 개인정보 처리금지, 기술적·관리적 보호조치, 재위탁 제한, 수탁자에 대한 관리·감독, 손해배상 등 책임에 관한 사항을 계약서 등 문서에 명시하고, 수탁자가 개인정보를 안전하게 처리하는지를 감독하고 있습니다.

③ 위탁업무의 내용이나 수탁자가 변경될 경우에는 지체없이 본 개인정보 처리방침을 통하여 공개하도록 하겠습니다.

5. 정보주체와 법정대리인의 권리·의무 및 그 행사방법 이용자는 개인정보주체로써 다음과 같은 권리를 행사할 수 있습니다.

① 정보주체는 회사 에 대해 언제든지 다음 각 호의 개인정보 보호 관련 권리를 행사할 수 있습니다.

1. 개인정보 열람요구

2. 오류 등이 있을 경우 정정 요구

3. 삭제요구

4. 처리정지 요구

6. 처리하는 개인정보의 항목 작성

② 회사는 다음의 개인정보 항목을 처리하고 있습니다.

1.<가나아이앤티>

- 필수항목 : 이름, 연락처, 이메일

- 선택항목 :

7. 개인정보의 파기

회사는 원칙적으로 개인정보 처리목적이 달성된 경우에는 지체없이 해당 개인정보를 파기합니다. 파기의 절차, 기한 및 방법은 다음과 같습니다.

-파기절차

이용자가 입력한 정보는 목적 달성 후 별도의 DB에 옮겨져(종이의 경우 별도의 서류) 내부 방침 및 기타 관련 법령에 따라 일정기간 저장된 후 혹은 즉시 파기됩니다. 이 때, DB로 옮겨진 개인정보는 법률에 의한 경우가 아니고서는 다른 목적으로 이용되지 않습니다.

-파기기한

이용자의 개인정보는 개인정보의 보유기간이 경과된 경우에는 보유기간의 종료일로부터 5일 이내에, 개인정보의 처리 목적 달성, 해당 서비스의 폐지, 사업의 종료 등 그 개인정보가 불필요하게 되었을 때에는 개인정보의 처리가 불필요한 것으로 인정되는 날로부터 5일 이내에 그 개인정보를 파기합니다.

8. 개인정보 자동 수집 장치의 설치·운영 및 거부에 관한 사항

회사는 정보주체의 이용정보를 저장하고 수시로 불러오는 ‘쿠키’를 사용하지 않습니다.

9. 개인정보 보호책임자 작성

① 회사는 개인정보 처리에 관한 업무를 총괄해서 책임지고, 개인정보 처리와 관련한 정보주체의 불만처리 및 피해구제 등을 위하여 아래와 같이 개인정보 보호책임자를 지정하고 있습니다.

▶ 개인정보 보호책임자

성명 :

직책 :

연락처 : 054-532-5519

이메일 :

※ 개인정보 보호 담당부서로 연결됩니다.

▶ 개인정보 보호 담당부서

부서명 : 가나아이앤티

담당자 :

연락처 : 054-532-5519

이메일 :

② 정보주체께서는 회사 의 서비스(또는 사업)을 이용하시면서 발생한 모든 개인정보 보호 관련 문의, 불만처리, 피해구제 등에 관한 사항을 개인정보 보호책임자 및 담당부서로 문의하실 수 있습니다. 회사는 정보주체의 문의에 대해 지체 없이 답변 및 처리해드릴 것입니다.

10. 개인정보 처리방침 변경

① 이 개인정보처리방침은 시행일로부터 적용되며, 법령 및 방침에 따른 변경내용의 추가, 삭제 및 정정이 있는 경우에는 변경사항의 시행 7일 전부터 공지사항을 통하여 고지할 것입니다.

11. 개인정보의 안전성 확보 조치 회사는 개인정보보호법 제29조에 따라 다음과 같이 안전성 확보에 필요한 기술적/관리적 및 물리적 조치를 하고 있습니다.

① 개인정보 취급 직원의 최소화 및 교육

개인정보를 취급하는 직원을 지정하고 담당자에 한정시켜 최소화 하여 개인정보를 관리하는 대책을 시행하고 있습니다.

기타 개인정보침해에 대한 신고나 상담이 필요하신 경우에는 아래 기관에 문의하시기 바랍니다.

1.개인분쟁조정위원회 (www.1336.or.kr/1336)

2.정보보호마크인증위원회 (www.eprivacy.or.kr/02-580-0533~4)

3.대검찰청 인터넷범죄수사센터 (http://icic.sppo.go.kr/02-3480-3600)

4.경찰청 사이버테러대응센터 (www.ctrc.go.kr/02-392-0330)